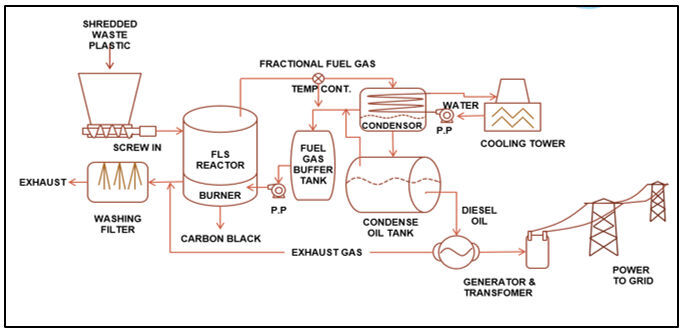

Fractional Liquefaction System

Turbul developed the FLS fractional liquefaction system (Fractional Liquefaction System), which is suitable for circular economy oil production for the treatment of waste plastics and waste tires. Target. The whole system is shown in the figure below. The shredded waste plastic sheets are sent to the uniform temperature pyrolysis reactor, and the pyrolysis and temperature-controlled fractionation reactions are carried out under the operation of 400-600°C, and then the diesel fuel gas separated by condensation of the fuel gas can be produced. The generator produces electricity, and the uncondensed combustible gas is sent back to the combustion furnace as fuel for self-use. The combustion gas is washed and discharged, and the solid carbon ash after the cracking reaction is completed is discharged from the bottom.

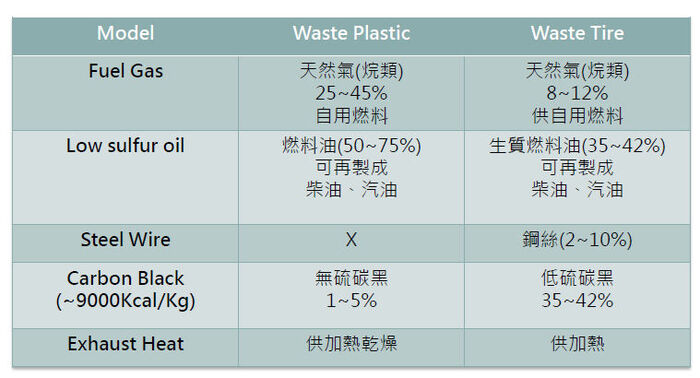

PRODUCT

FLS inorganic resource recovery product

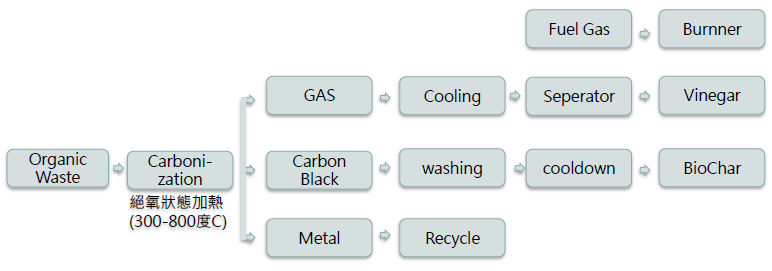

FLS Organics Charring Run

Resource cycle diagram - schematic diagram of fuel oil power generation